Post by markeb01 on Sept 10, 2009 22:45:32 GMT -7

I wanted the appearance of a 327 Corvette engine on a 350 Chevy. I did a bunch of internet research and found no viable solution, so I came up with my own.

Following is one method to run early style sealed valve covers on a later small block - not having the road draft tube for crankcase venting. Most installations of this type I’ve seen have a hole punched in the top or side of the valve cover spoiling the cosmetic effect, or the smog hose connected to the oil fill tube just below the breather cap where it doesn’t vent the crankcase properly.

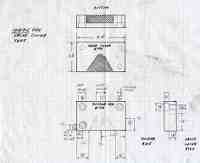

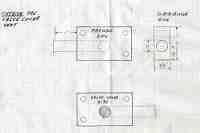

After careful analysis of the rocker arm to valve cover clearance, I was convinced a smog vent could be successfully connected to the rear of the passenger side valve cover where it would be difficult to detect. I designed the 2 piece adapter shown, and my son machined it out of aluminum. He made a few improvements from the drawings by substituting stainless flat head screws threaded into the external half of the adapter. The inside piece forms a shroud allowing oil to splash against the end wall and drain back into the head, much like a stock baffle. The external half provides the connection for the smog hose. In a conventional engine compartment the finished installation is nearly invisible. The smog hose routes behind the distributor (hiding the smog valve at the rear of the manifold) and comes up on the drivers side, attaching to the rear of the carb via a fitted hard line.

Attached are photos of the finished installation, component parts, along with the original drawings for the adapter pieces. After drilling holes in the rear of the valve cover, the two parts were assembled using red Loctite, cork gasket material inside, and thin composite material outside. The steel tube was a tight slip fit into the external adapter also adhered with red Loctite. There have been no oil control issues with this setup. The schematic does not indicate the curved hard tube which ultimately provided the best angle to hide the hose. If further stealth is required more effort could be put into the final shape of the external half of the adapter.

Since the Corvette covers are short, this method should also work with stock tin covers, Mickey Thompsons, or any type with a somewhat flat end wall. This arrangement may have clearance problems with roller rockers.

URL=http://img25.imageshack.us/i/101vas.jpg/] [/URL]

[/URL]

URL=http://img7.imageshack.us/i/107hzk.jpg/] [/URL]

[/URL]

Following is one method to run early style sealed valve covers on a later small block - not having the road draft tube for crankcase venting. Most installations of this type I’ve seen have a hole punched in the top or side of the valve cover spoiling the cosmetic effect, or the smog hose connected to the oil fill tube just below the breather cap where it doesn’t vent the crankcase properly.

After careful analysis of the rocker arm to valve cover clearance, I was convinced a smog vent could be successfully connected to the rear of the passenger side valve cover where it would be difficult to detect. I designed the 2 piece adapter shown, and my son machined it out of aluminum. He made a few improvements from the drawings by substituting stainless flat head screws threaded into the external half of the adapter. The inside piece forms a shroud allowing oil to splash against the end wall and drain back into the head, much like a stock baffle. The external half provides the connection for the smog hose. In a conventional engine compartment the finished installation is nearly invisible. The smog hose routes behind the distributor (hiding the smog valve at the rear of the manifold) and comes up on the drivers side, attaching to the rear of the carb via a fitted hard line.

Attached are photos of the finished installation, component parts, along with the original drawings for the adapter pieces. After drilling holes in the rear of the valve cover, the two parts were assembled using red Loctite, cork gasket material inside, and thin composite material outside. The steel tube was a tight slip fit into the external adapter also adhered with red Loctite. There have been no oil control issues with this setup. The schematic does not indicate the curved hard tube which ultimately provided the best angle to hide the hose. If further stealth is required more effort could be put into the final shape of the external half of the adapter.

Since the Corvette covers are short, this method should also work with stock tin covers, Mickey Thompsons, or any type with a somewhat flat end wall. This arrangement may have clearance problems with roller rockers.

URL=http://img25.imageshack.us/i/101vas.jpg/]

[/URL]

[/URL]

URL=http://img7.imageshack.us/i/107hzk.jpg/]

[/URL]

[/URL]

anyone know if its possible to turn my c10 into 4x4 ?

anyone know if its possible to turn my c10 into 4x4 ?